IML

In-Mould Labels Printing Suppliers

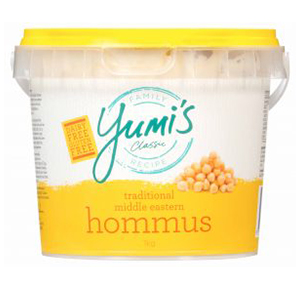

Ensure your product stands out from the crowd with in-mould labelling (IML) solutions from Fantastick Label Company. IML printing allows you to give your packaging a bold, unique and colourful appearance. We are Melbourne’s leading suppliers of in-mould labels. Our knowledgeable and experienced team will take the time to understand your application and branding requirements to deliver a tailor-made solution to suit your needs. We are committed to delivering our clients high quality results, prompt communication, and friendly customer service. Contact us today for a free quote.

Ensure your product stands out from the crowd with in-mould labelling (IML) solutions from Fantastick Label Company. IML printing allows you to give your packaging a bold, unique and colourful appearance. We are Melbourne’s leading suppliers of in-mould labels. Our knowledgeable and experienced team will take the time to understand your application and branding requirements to deliver a tailor-made solution to suit your needs. We are committed to delivering our clients high quality results, prompt communication, and friendly customer service. Contact us today for a free quote.

WHAT IS IN-MOULD LABEL PRINTING?

It is an extremely precise process where the printed plastic label is loaded into the mould. The product (container, lid or component) is then moulded behind and around the label.

InMould Labelling

In short, container and label become one. This bond formed between the product and the label is better than “printed-on” or adhesive graphics.

It is an extremely precise process where the printed plastic label is loaded into the mould. The product (container, lid or component) is then moulded behind and around the label.

In short, container and label become one. This bond formed between the product and the label is better than “printed-on” or adhesive graphics.

In Mould Labelling Has Many Advantages Over Traditional Labeling:

- It offers maximum print quality, allowing your designers to really go to town on that design and make your product and brand stand out.

- The offset printing of the label produces high-resolution outcomes, including photography, and allows for the label to wrap around the entire container.

- In mould labels are scratch resistant, they can’t crack and they aren’t susceptible to wrinkles!

- They are also strong and hygienic and resist big changes in temperature, making them ideal for frozen and refrigerated products.

- The process offers shorter production time and lower production costs.

- IML is more environmentally friendly as the packaging and the label consist of the same material and can therefore be fully recycled.

IML PRINTING – MARKETS WE SERVE

We offer this cutting edge printing solution for a variety of contract packaging products and applications. We supply to the fast-moving consumer goods industry including horticultural, food & beverage, industrial and dairy. Various embellishments could be added to the labels, such as cold foil, spot gloss or matt varnish, high build print and variable data print.

Applications include reusable drinking cups, lunch boxes, kitchen products, dustbins, storage containers and packaging products such as barrels, pails, tubs, and cartridges.

Whether you are packaging cheese, butter, confectionery, ice cream, pet food, paint, tobacco, yogurt, salads or spreads, we work with you to create a custom solution to suit your brand and product.

FEATURES OF IN-MOULD PRINTING

FEATURES OF IN-MOULD PRINTING

- Extremely durable

- Fade-resistant

- Scratch-resistant

- Lower production costs

- Shorter production time

- Eco-friendly

- 100% recyclable

- No adhesives

- Available in gloss, matte and metallic finishes

- Excellent print quality

- Improves container strength

Request a Quote

When you are looking for high-quality in-mould labelling suppliers in Melbourne, look no further. Contact FLC today for beer labels, sticky labels, cosmetic labels or request a custom quote.

OUR HAPPY CLIENTS

1,00 000+ business professionals trust us with their printing. Add the real human face or even you can

approach your existing customers or reputed businesses for testimonial.

Again, thanks for your attention to detail and picking the errors for us.

Srini Ranganathan | Co- founder and CEO Euclove Clean Pty Ltd.

Thank you so much! It sounds perfect! Really Efficient.

Giancarlo Leonardi | Processes Manager – Operations Dept Diseb Group Pty Ltd

The labels have arrived – which is amazing ! They were scanned in at Devonport this morning at 8.45 am – which made me think we wouldn’t get them until tomorrow, but amazingly they are here – and with two days to spare. You are the best – thank you so much for the efficiency in meeting our urgent requirements.

Teena Blair | Office Manager R Stephens Apiarists Pty Ltd

Thank you so much for your efforts in sorting out our orders and accounts! Appreciate it.

Lidija Rafailovic | Warehouse General Hand Australian Pharmaceuticals Manufacturers

Great result on this month’s stock reconciliation. This is very impressive considering how busy the last month has been. Thank you for your hard work and diligence in managing our stock.

Anthony Sheehan | Short Term Planner PPD L’Oréal Australia

We just wanted to reach out and say thank you for such lovely labels. They’re exactly what we were hoping for. I’ve attached a picture so you can see our final product and look out for it on the shelves! 🙂

Matt and Isabella Brunswick Burn Co- Founder and CEO

Fantastick Labels have been providing us with labels for 35 years – over that time many designs and sizes have been designed and printed. Their staff are professional, friendly and efficient and go above and beyond at times to ensure labels are delivered on time or to get artwork finalized to exactly what we require. We always feel we are a priority even with the smallest of orders. Fantastick are like family to us, we wouldn’t buy anywhere else.

Tina Blair R. Stephens Apiarists Pty Ltd

I have been working with Fantastick for over 20 years and have always enjoyed the great service and pricing. The team has been attentive to our changing requirements and getting product delivered on time.

Martin Talacko I Managing Director SalDoce Fine Foods

Our experience with Fantastick Label Co over the past 16 months as contributed to the success of our business. With exceptionally professional staff and process in places, their timely services and aptitude to our projects as yield success to our intricate business portfolio.

Keenan Adonis | International Sales Director S K Trading & Sons Pty Ltd

Edlyn Foods and Fantastick Label Company have been partners for a number of years. During this time, the team at FLC have demonstrated an extremely high level of commitment and dedication when it comes to their products and services. This in turn allows Edlyn Foods to provide value to its customers. I look forward to a continued lasting relationship with FLC in the future

Joey Kuruvilla | Procurement Manager Edlyn Foods Pty Ltd

Recommended Products

Subscribe to the Newsletter